Zamak items

Manufacturing aesthetic items in zamak is

our core business. All the stages in the production process

are carried out on site - designing the die, the actual die-casting

process, surface finishing, galvanization or decorative treatment,

and lastly packaging.

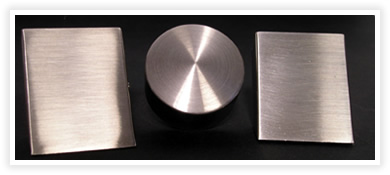

Surface finishing of a die-cast item is a

strategic stage in the whole cycle if a good finished product

is to be obtained – preparing a good under-surface

makes the galvanisation process much easier.

We perform lapping, polishing, satin-finishing and vibrating,

as well as the mechanical processes of drilling and tapping.

Our zamak items undergo galvanisation processes

to give polished chrome, nickel, matt nickel and satin nickel

finishes, but we also supply items colour-painted, varnished

or sanded. An interesting new treatment is SIMILINOX, which

gives a stainless steel look on a zamak base.

This treatment is ideal for zamak items assembled with stainless

steel components to give a uniform finish.

|